Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

This product is mineral water bottle cap injection PP mould. The precision of PP cap molds ensures uniform dimensions and features across produced caps, allowing for reliable sealing and compatibility with corresponding containers. Automation in injection molding processes minimizes the need for manual labor, reducing...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

This product is unscrewing mold for bottle cap injection moulding. PP (polypropylene) cap molds are specialized tools used in the injection molding process to manufacture caps and closures used in various industries, such as beverages, cosmetics, pharmaceuticals, and more. These molds offer several advantages that...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Transportation: Express,Air,Land,Ocean

Product Color: According to customer requiremen

Inspection Certification: FAI, CPK IQC, IPQC, OQC.

Product process: Thermos bottle plastic bottle cap is made of PP material that thermos injection mould has 1*2 cavities. It is produced by mould insert Steel S136 and cold runner. Production quality: Hongke mold specializes in studying manufacturing bottle caps mould and injection molding production, with 16 years of...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

This product is PP injection molding for water bottle cap. Caps are often produced in large quantities. PP cap molds are optimized for fast cycle times, enabling high-volume production and meeting the demands of the packaging industry, can be tailored to accommodate various cap sizes, shapes, and features, including...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

This product is a Water Bottle Cap Injection Mold. The material of this product is PP material. This is also a set of Unscrewing Mould. The high-speed production capability of injection molding results in efficient manufacturing processes, meeting the demand for timely production in the Water Bottle industry. The...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Transportation: Ocean,Land,Air,Express

Company advantage: Hongke mold specializes in cap mold making and injection molding, with 16 years of experience in injection mould. Hongke focuses on creating diversified wine drinks cap injection mould and drinks Caps moulding for customers, the company pays attention to the production quality of Wine bottle plastic...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Air,Land,Express

Mould Size: According to the plastic product/3D drawing

Caps mould is one of our common mold making cases. Caps mold usually needs to meet the needs of mass production of bottle caps, so this mold is designed with a cavity of 1*8 and a cold runner system. S136 mold steel is used for this mold making, mold life can be 1,000,000 shots or more. The surface finish of the mold...

Packaging: Wooden box

Supply Ability: Export about 400-500 set moulds per year

Transportation: Ocean,Land,Air,Express,Express

Mould Size: According to the plastic product/3D drawing

Mould Base Steel: S50C

Plastic caps mould development, various

plastic caps mould design, mold making and injection molding, Hongke Mold has

more than 20 years of manufacturing experience. Caps mould are widely used in food,

beverage, pharmaceutical, cosmetics and other industries. Bottle caps of

various shapes can be produced using bottle...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year

Transportation: Ocean,Land,Air,Express

Product Color: According to customer requirement

Mould Base Steel: S136

Please kindly check our high-quality, high-temperature-resistant caps plastic injection mould product for home use! Made of PP material with good heat resistance. The caps mould is made of steel and can last upwards of 500,000 times if properly maintained. Meanwhile, we can make mineral water bottle cap mold. Our...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

Our fabrication of Caps mould is one of our extensive mold making portfolio. Usually meet the requirements of batch bottle cap production, this mold is meticulously crafted with a 1*8 cavity arrangement complemented by an advanced cold runner system. Employing the resilience of S136 mold steel, the mold attains an...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

The fabrication of Caps Mould represents a prevalent cases within our extensive mold production portfolio. This molds are strategically devised to fulfill the requisites of large-scale bottle cap manufacturing, leading to the creation of molds characterized by a meticulously crafted 1*8 cavity layout complemented by...

China Drinks Cap Mold Suppliers

Our company has 16 years of rich experience in the field of mold making, focusing on the production of precision injection mould for bottle cap plastics, demonstrating extremely high professionalism and technical strength. Especially in the production of beverage Drinks Cap Mold, our company is proficient in the entire process from design to production, and can provide customers with high-quality and high-precision products.

Our company strictly controls the quality of mold production to ensure that each process meets high standards and requirements. This practice not only improves production efficiency, but also reduces the defect rate, thus ensuring the high-quality performance of the final product.

Having a strong and professional design team is a big advantage of our company. These designers not only have rich industry experience and deep professional knowledge, but also can provide personalized customized solutions according to the specific needs of customers, to ensure that the design of the mold meets the requirements of use, but also has aesthetic.

You also attach great importance to communication and cooperation with customers, and are committed to meeting their various needs. Whether it is product performance, price or delivery time, your company is able to provide competitive solutions, which has won wide praise from customers.

We also attach great importance to communication and cooperation with customers, and are committed to meeting the various needs of customers. Whether it is product performance, price or delivery time, your company can provide competitive solutions and win wide praise from customers.

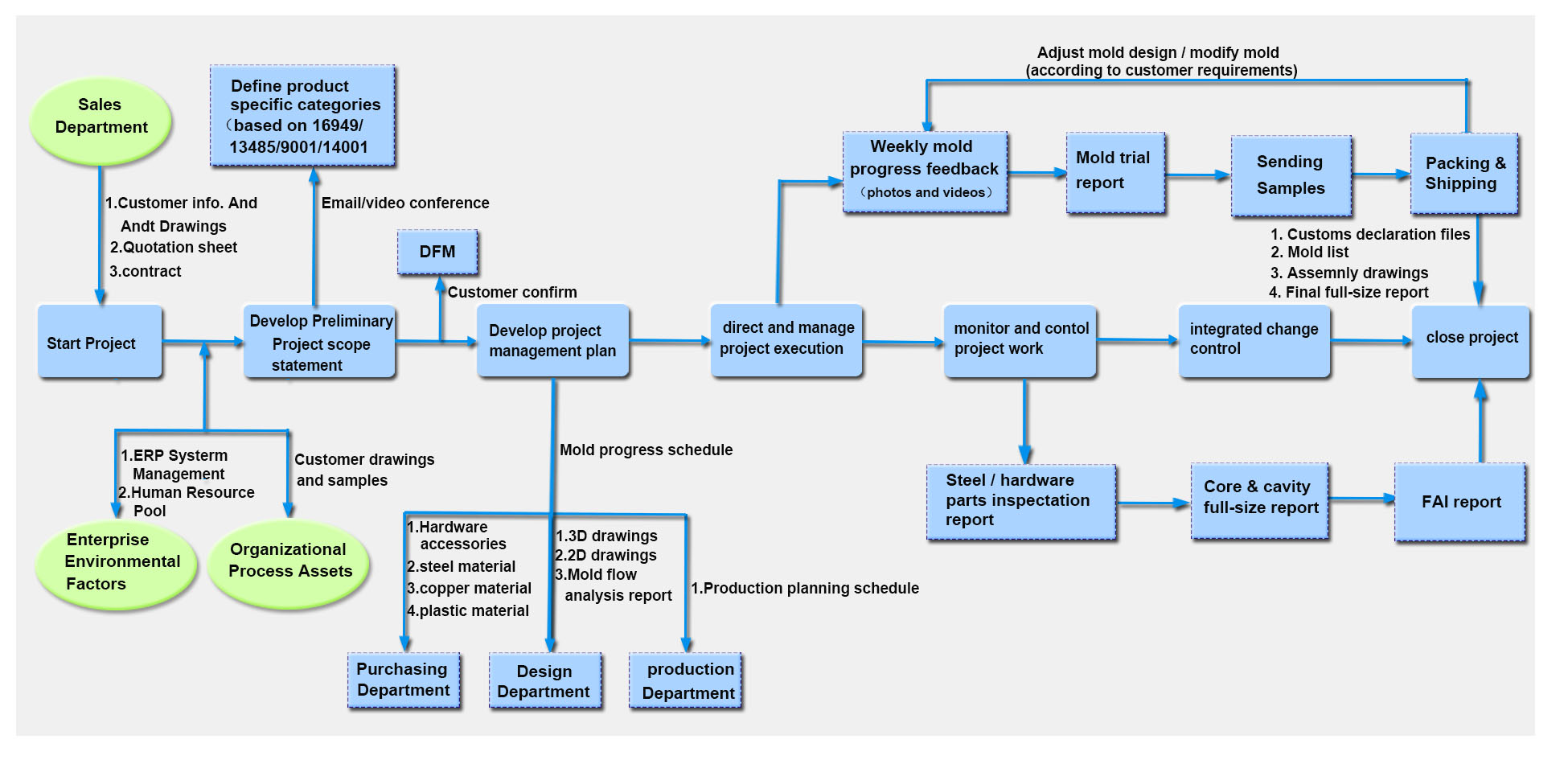

Production Flow Chart for Drinks Cap Mold

Home > Products > Caps Plastic Mould > Drinks Cap Mold

Send Inquiry

Ms. Sophia

Tel:86-0769-82289418

Fax:86-0769-82289428

Mobile Phone:+8613925855181

Email:sophia@hongkemould.com

Address:No.6, Xiangshan Road, Jichiling, Dalingshan town, Dongguan City, Guangdong Province, China, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.