Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Packaging: Wooden box

Supply Ability: Monthly production capacity of 40~60 sets depends on the mold structure

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

Mould Base Steel: S50C

Manufacturer of BMC mold making and

injection molding. Our company analyzes the BMC Mould making and injection

molding production process in advance. Through pre-assessment, engineers can

identify and control in advance to ensure the smooth and reliable production

process and stable product quality. In the BMC...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Place Of Origin: China

Introducing our Tooling Bulk Molding Compound (BMC) for BMC Plastic Mould, designed to deliver precision and performance in your molding processes. BMC demands meticulous temperature management to ensure optimal curing. Any variance in temperature can impact the curing rate and the final quality of the molded product,...

Packaging: Wooden box

Supply Ability: Monthly production capacity of 40~60 sets depends on the mold structure

Transportation: Ocean,Land,Air,Express,Others

Mould Size: According to the plastic product/3D drawing

Mould Base Steel: S50C

As an experienced factory, Hongke Mold has

achieved remarkable results in the field of injection molding of plastic

injection molds and BMC material part molds with its professional development,

design and manufacturing capabilities. By obtaining ISO9001:2015, IATF

16949:2016, ISO13485:2016 and ISO14001:2015...

Packaging: Wooden box

Supply Ability: Monthly production capacity of 40~60 sets depends on the mold structur

Transportation: Ocean,Land,Air,Express,Express

Mould Size: According to the plastic product/3D drawing

Mould Base Steel: S50C

Customized

electrical housing BMC mold making and injection molding. In

the field of electrical and electronics, BMC parts mould are widely used to

produce insulation parts, circuit breaker housings, sockets, etc. These

products have high requirements for heat resistance and electrical resistance,

and the excellent...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express,Express

Mould Size: According to the plastic product/3D drawing

The product is BMC Precision Mould For Plastic Molding. BMC undergoes shrinkage during curing. The mold must be designed to accommodate this shrinkage to ensure the final part meets dimensional specifications. Designing molds for complex shapes requires advanced techniques to ensure complete filling and proper...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express,Express

Mould Size: According to the plastic product/3D drawing

The product is BMC Bulk Molding Compound Injection Molding Tooling. BMC material has a specific viscosity that must be managed during molding to ensure even distribution throughout the mold. Inadequate flow can lead to defects such as voids or incomplete filling. In the mold processing process, the mold insert steel...

Packaging: Wooden box

Supply Ability: Monthly production capacity of 40~60 sets depends on the mold structure

Transportation: Ocean,Land,Air,Express,Others

Mould Size: According to the plastic product/3D drawing

Mould Base Steel: S50C

Our company is a professional manufacturer

of customized BMC Precision Mould and BBMC

Material Mold. With professional customization and production capabilities, we

can provide high-precision BMC molds that meet your needs. In addition to

manufacturing high-quality BMC plastic Mould, we also value...

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express

Mould Size: According to the plastic product/3D drawing

Product color: According to the plastic product/3D drawing

Quality Certification: ISO9001:2015, SGS, TÜV

Professional Degree of The Company: The company has been engaged in mold making for 16 years, has a very rich experience in plastic precision injection mold making, proficient in the mold making from design to production, BMC plastic injection mould is one of the molds that our company is good at making from the...

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Min. Order: 1 Set/Sets

Transportation: Ocean,Air,Land,Express

Mould Size: According to the plastic product/3D drawing

Product material advantage: BMC is a special composite material, usually composed of polyester resin, filler materials (such as glass fiber, short fiber, etc.) and additives, with the characteristics of high strength, corrosion resistance, strong insulation, high temperature resistance and plasticity. Product...

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Min. Order: 1 Set/Sets

Transportation: Ocean,Land,Air,Express,Express

Mould Size: According to the plastic product/3D drawing

The product is Tooling Bulk Molding Compound For BMC Plastic Mould. BMC requires precise temperature control to cure properly. Deviations in temperature can affect the curing rate and final properties of the molded part. Uneven heating can lead to internal stresses and warping. Consistent temperature across the mold...

China Bulk Molding Compound Suppliers

Bulk Molding Compound (BMC) mold making and injection molding manufacturers are companies that focus on using BMC, a semi-dry method to manufacture glass fiber reinforced thermosetting products, as a molding intermediate material, to carry out high-precision mold making and injection molding production.

Professional technology and experience: We have been committed to the research, development and production of BMC materials for a long time and have accumulated rich professional technology and experience. We have a deep understanding of the characteristics of BMC materials, processing technology and mold design, and can provide customers with high-quality BMC Mould and injection molding products.

Advanced production equipment: We have advanced mold manufacturing equipment and injection molding production equipment, including high-precision CNC machine tools, electric discharge processing machines, injection molding machines, etc., to ensure the accuracy of molds and the quality of injection molding products.

Customized service: We can provide customized precision BMC plastic injection Mould manufacturing and injection molding production solutions according to customers' specific needs and product design. From product design, mold manufacturing to injection molding production, we provide one-stop service to meet customers' personalized needs.

Strict quality control: Strict quality control is carried out on raw materials, production processes and final products to ensure that the products meet customers' standards and requirements. By implementing a strict quality management system, we can improve production efficiency and product quality.

After-sales service: We provide comprehensive after-sales service, including technical support, mold maintenance and repair, etc. When customers encounter problems during use, we can respond in time and provide solutions to ensure the smooth production of customers.

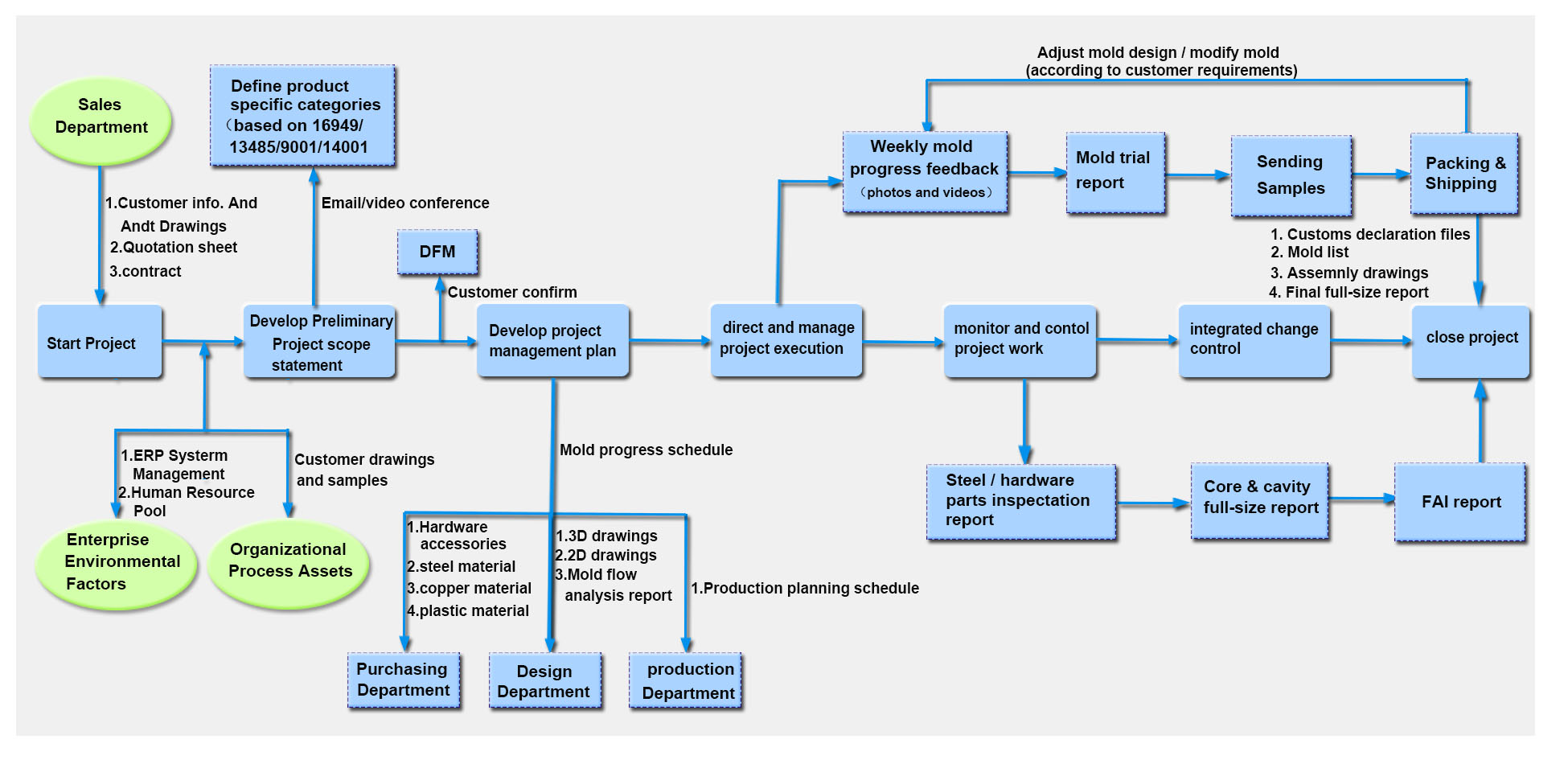

Production Flow Chart for Bulk Molding Compound

Send Inquiry

Ms. Sophia

Tel:86-0769-82289418

Fax:86-0769-82289428

Mobile Phone:13925855181

Email:sophia@hongkemould.com

Address:No.6, Xiangshan Road, Jichiling, Dalingshan town, Dongguan City, Guangdong Province, China, Dongguan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.